Kwatanta tsarin kayan da'irar da aka haɗa da photonic

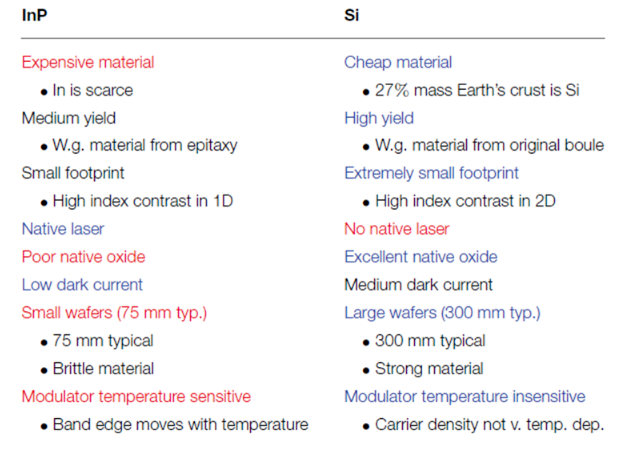

Hoto na 1 ya nuna kwatancen tsarin abu guda biyu, indium Phosphorus (InP) da silicon (Si). Rashin ingancin indium ya sa InP ya fi tsada fiye da Si. Saboda da'irori masu tushen silicon sun ƙunshi ƙarancin girma na epitaxial, yawan amfanin da'irori masu tushen silicon yawanci ya fi na da'irori masu tushen InP. A cikin da'irori masu tushen silicon, germanium (Ge), wanda yawanci ana amfani da shi ne kawai a cikinMai gano hoto(na'urorin gano haske), yana buƙatar girma a epitaxial, yayin da a cikin tsarin InP, har ma da jagororin raƙuman ruwa masu wucewa dole ne a shirya su ta hanyar girma a epitaxial. Girman Epitaxial yana da yawan lahani mafi girma fiye da girma a cikin lu'ulu'u ɗaya, kamar daga ingot na lu'ulu'u. Jagoran raƙuman ruwa na InP suna da babban bambancin ma'aunin haske kawai a cikin transverse, yayin da jagororin raƙuman ruwa na silicon suna da babban bambancin ma'aunin haske a cikin transverse da longitudinal, wanda ke ba da damar na'urorin da ke tushen silicon su sami ƙananan radiyo masu lanƙwasa da sauran ƙananan tsari. InGaAsP yana da tazara kai tsaye ta band, yayin da Si da Ge ba su da. Sakamakon haka, tsarin kayan InP sun fi kyau dangane da ingancin laser. oxides na intrinsic na tsarin InP ba su da ƙarfi da ƙarfi kamar oxides na intrinsic na Si, silicon dioxide (SiO2). Silicon abu ne mai ƙarfi fiye da InP, yana ba da damar amfani da manyan girman wafer, watau daga 300 mm (nan ba da jimawa ba za a haɓaka zuwa 450 mm) idan aka kwatanta da 75 mm a cikin InP. InP.masu daidaitayawanci yana dogara ne akan tasirin Stark wanda aka killace shi da quantum, wanda ke da saurin kamuwa da yanayin zafi saboda motsi na gefen band wanda zafin jiki ke haifarwa. Sabanin haka, dogaro da zafin jiki na masu daidaita silikon ba shi da yawa.

Gabaɗaya ana ɗaukar fasahar silicon photonics ta dace ne kawai da samfuran masu rahusa, gajere, da kuma masu yawan gaske (fiye da guda miliyan 1 a kowace shekara). Wannan saboda an yarda cewa ana buƙatar babban adadin wafer don yaɗa abin rufe fuska da kuɗaɗen haɓakawa, kuma hakan yana nufin cewafasahar silicon photonicsyana da manyan rashin inganci a aikace-aikacen samfura na birni zuwa birni da na dogon lokaci. Duk da haka, a zahiri, akasin haka gaskiya ne. A cikin aikace-aikacen masu rahusa, gajere, masu yawan amfanin ƙasa, laser mai fitar da saman rami a tsaye (VCSEL) dalaser mai daidaitawa kai tsaye (Laser DML) : laser mai daidaitawa kai tsaye yana haifar da babban matsin lamba na gasa, kuma raunin fasahar photonic mai tushen silicon wanda ba zai iya haɗa lasers cikin sauƙi ba ya zama babban rashi. Sabanin haka, a cikin metro, aikace-aikacen nesa, saboda fifikon haɗa fasahar silicon photonics da sarrafa siginar dijital (DSP) tare (wanda galibi yana cikin yanayin zafi mai yawa), yana da fa'ida a raba laser ɗin. Bugu da ƙari, fasahar ganowa mai haɗin gwiwa na iya rama ƙarancin fasahar silicon photonics zuwa babban mataki, kamar matsalar cewa hasken rana mai duhu ya fi ƙanƙanta fiye da hasken oscillator na gida. A lokaci guda, ba daidai ba ne a yi tunanin cewa ana buƙatar babban adadin ƙarfin wafer don rufe farashin abin rufe fuska da haɓakawa, saboda fasahar silicon photonics tana amfani da girman nodes waɗanda suka fi girma fiye da mafi girman ci gaban semiconductors na ƙarfe oxide (CMOS), don haka abin rufe fuska da ayyukan samarwa da ake buƙata suna da arha.

Lokacin Saƙo: Agusta-02-2024